Ah, yard work—a peaceful communion with nature, right? Except when your bushes have mutated into an impenetrable fortress that mocks your puny tools.

(The overgrown bushes that started it all—my DIY brush cutter’s first worthy opponent.)

Enter: the DIY brush cutter. I could’ve gone to the store and bought a fancy one, but where’s the fun in that? Instead, I decided to harness the power of science, some PVC pipes, and a DC motor. The result? A tool that’s part weapon, part lawn care, and 100% awesome. Buckle up, because I’m about to take you on a wild ride through the world of DIY engineering.

Materials and Tools Required

Let’s start with the shopping list—because every good adventure begins with a quest:

- DC Motor: 12V, 2A motor, aka the little engine that could… theoretically.

- PVC Pipes: 1-inch and 3/4-inch pipes—because nothing says “I mean business” like plastic tubing.

- Blades: Sharp metal discs that make you feel like a mix between MacGyver and a Jedi.

- PVC Reducer, Joints, Cap: To make sure everything aligns perfectly (or close enough).

- Power Supply: 12V, 2A adapter—basically the electric heart of this beast.

- Switch: So you can turn this bad boy on and off like a boss.

- Wiring and Connectors: To make sure the electricity goes where it’s supposed to, and not, you know, into your hands.

- Miscellaneous: Screws, tape, zip ties—because DIY without zip ties is like a sandwich without bread.

Tools used:

- Saw: For cutting pipes, not for playing horror movie soundtracks.

- Drill: For when you need a hole, and you need it now.

- Soldering Iron: Because you’re not really a maker until you’ve soldered something.

- Screwdriver and Wrenches: For those moments when brute force won’t cut it.

Step-by-Step Construction Process

1. Design and Planning

First, I channeled my inner Tony Stark (minus the billion-dollar budget) and sketched out my design. The idea was simple: build something that can take down the jungle in my backyard without taking down me in the process. I knew PVC pipes were the answer—lightweight, cheap, and the backbone of many a DIY masterpiece.

2. Assembling the Frame

The frame is the exoskeleton of this DIY brush cutter—a skeleton made of plastic, but don’t let that fool you.

- Step 1: Cut a 1-inch PVC pipe to about 1.3m—just long enough to keep the blades away from your legs, because, you know, safety.

- Step 2: Add a 45 elbow to the pipe and connected it to a 75×50 reducer.

- Step 3: Secure everything with screws and PVC glue, because duct tape may be the Force that holds the universe together, but we’re aiming for a bit more finesse here.

(Assembling the PVC frame—getting closer to a working brush cutter.)

3. Mounting the Motor

Here’s where things get interesting. I needed to make sure the motor was as secure as the Wi-Fi router after a firmware update.

- Step 1: Attach the motor to a reducer—a small but mighty piece of hardware that made sure the motor didn’t wobble like a bobblehead. Close the end of reducer with PVC Cap and screw the motor to the cap.

- Step 2: Connect that reducer to a PVC pipe using an elbow joint, giving the whole setup a sleek, “I totally know what I’m doing” look.

- Step 3: Double-check the alignment, because nothing says “disaster waiting to happen” like a misaligned motor and spinning blades.

(The motor mounted securely with the end cap and reducer.)

4. Attaching the Cutting Mechanism

Let’s talk about the business end of this tool—the part that slices, dices, and maybe even juliennes (I haven’t tried it in the kitchen yet).

- Step 1: Secure the metal blades to the motor shaft. These aren’t just any blades—they’re like the DIY Excalibur, ready to mow down anything in their path.

- Step 2: Make sure the blades are balanced and tightened, because the last thing you want is a rogue blade deciding it’s had enough of this job.

- Step 3: Spin test! (Cue dramatic music.) If the blades rotate smoothly and don’t sound like an impending disaster, you’re good to go.

(The cutting mechanism—sharp, shiny, and ready for action.)

5. Wiring and Power Supply

Electricity is the lifeblood of this creation. Let’s make sure it flows where it’s supposed to, not where it’ll give you a new hairstyle.

- Step 1: Solder the wires to the motor terminals. Soldering is like crafting, but with fire and molten metal.

- Step 2: Connect these wires to the switch, giving you the power to control your creation—muahaha!

- Step 3: Secure the wiring with zip ties. This isn’t just for looks—those cables aren’t going anywhere now.

(Wiring and assembly in progress—it’s starting to look like something real!)

6. Final Assembly and Testing

You’ve come this far. Now it’s time to assemble everything and hope it doesn’t explode on the first try.

- Step 1: Tighten all screws and bolts. You’re not just tightening screws—you’re sealing your destiny.

- Step 2: Plug in the power supply, flip the switch, and behold: the DIY brush cutter in all its glory.

- Step 3: Take it for a spin outside. If it works, congratulate yourself on being a genius. If not, well, you’ve got a good story to tell.

(The moment of truth—testing the brush cutter on real bushes.)

Performance and Results

So, how did my DIY brush cutter fare? It was like a lightsaber in the garden—cutting through light to moderate brush with ease. But when it came to the thick, tough stuff, it was more like a butter knife in a steakhouse. The motor gave its all, but sometimes it just wasn’t enough. Still, for a first attempt, it was a solid win. Plus, I now have an excuse to upgrade to a more powerful motor—because who doesn’t love an upgrade?

(The aftermath—bushes defeated, DIY skills leveled up.)

Lessons Learned and Tips

- Motor Power: If you want to cut through bushes thicker than a phone book, consider a motor with higher torque. Or just get a chainsaw and call it a day.

- Safety First: Seriously, don’t skip the safety gear. This thing is awesome, but it’s not worth losing a limb over.

- Improvement Plans: I’m already dreaming up version 2.0—bigger, better, and hopefully with fewer motor stalls.

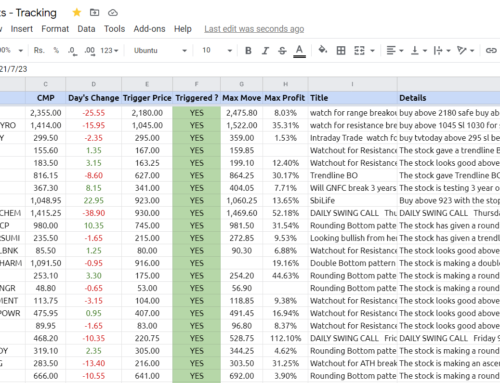

Cost of Items

- Motor – Rs.200/-

- DC Adapter – Rs.150/-

- PVC Pipe, Elbow, Reducer, Cap etc – Rs.150/-

- Blade – Rs.100/-

* Cost is rounded off for easy calculation.

Conclusion

Building a DIY brush cutter was like a rite of passage into the world of makers. Sure, there were moments of doubt (and a few close calls with those spinning blades), but in the end, it was totally worth it. If you’re the type who likes to tinker, build, and create, I say go for it. There’s nothing quite like wielding a tool you built with your own hands—especially one that can turn an overgrown yard into a tidy garden.

So, what are you waiting for? Get out there and start building—and may the PVC be with you!

Here is the testing video,

Leave A Comment

You must be logged in to post a comment.